Printable Bolt Torque Chart

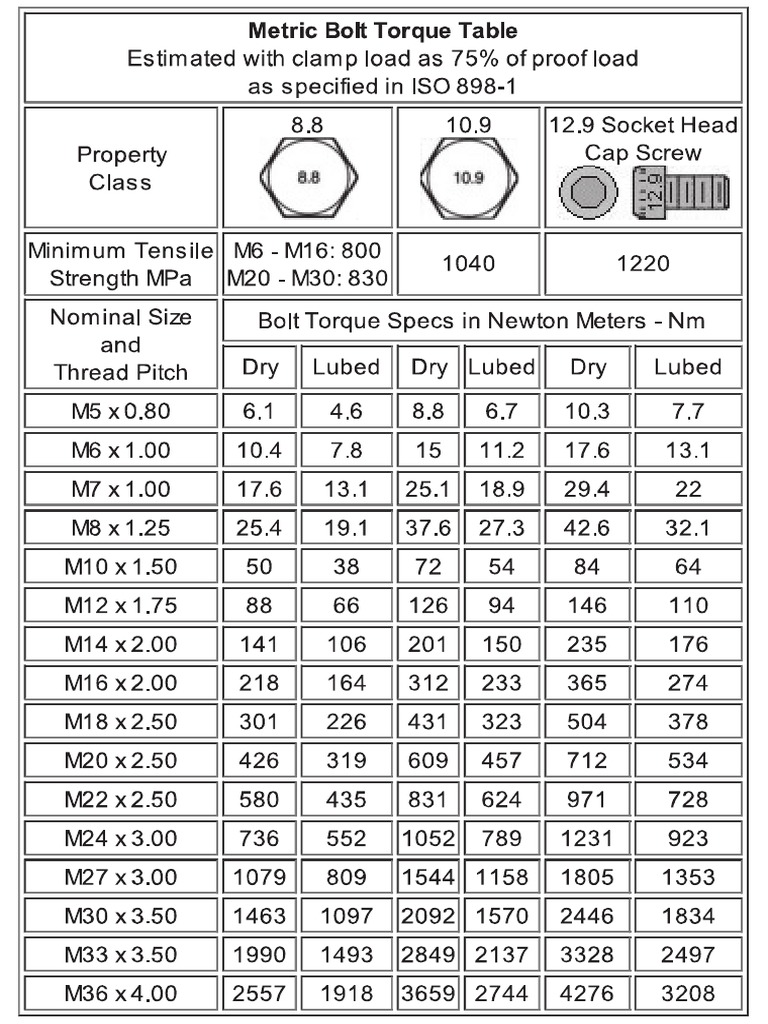

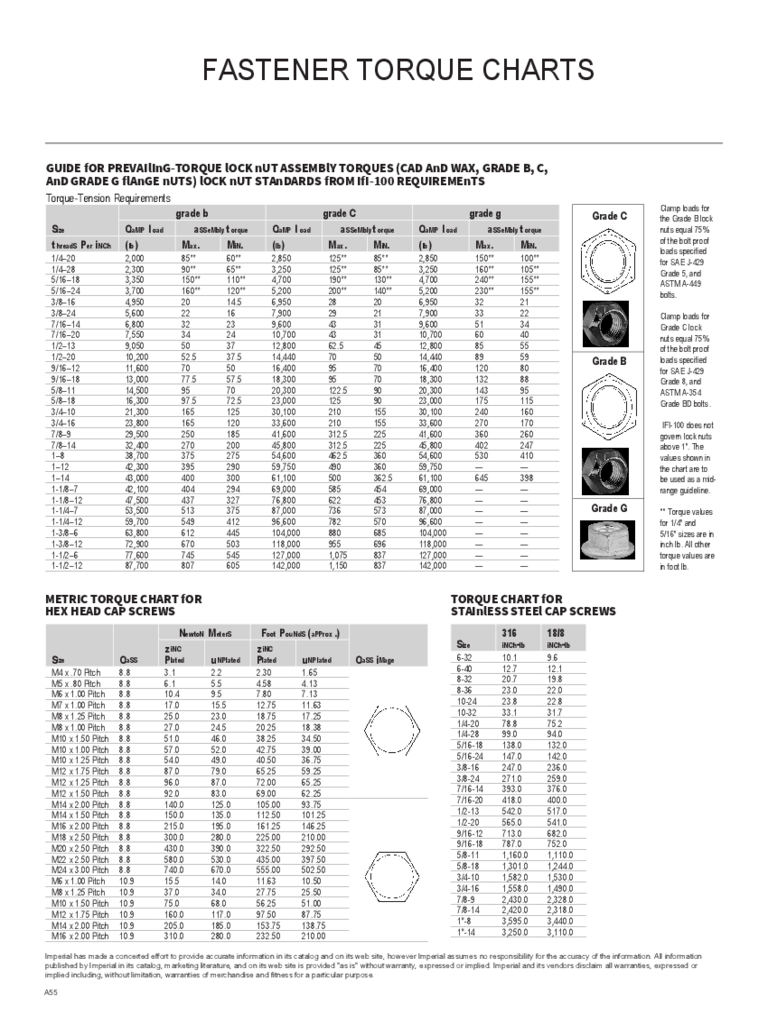

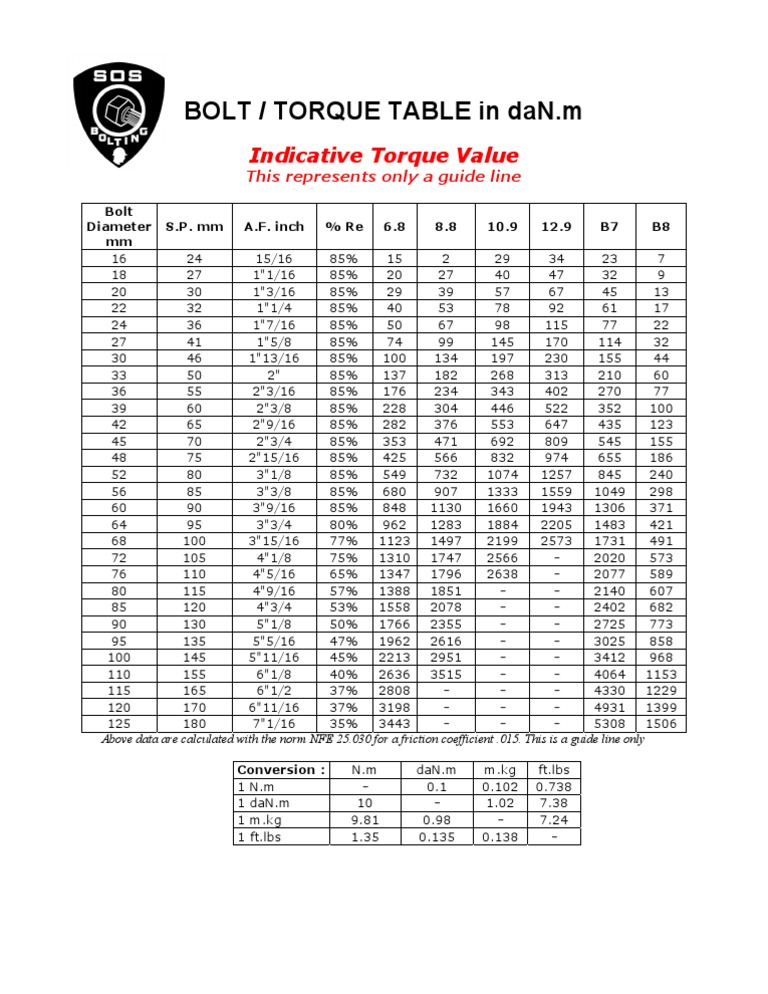

Printable Bolt Torque Chart - Pdf (portable document format) is a file format that captures all the. Style c charts list specifications and torque tightening guidelines for alloy steel socket screws. Bolt and nut are both phosphated; These values should only be used when the machine manufacturer has not provided their own. Metric bolts, screws & nuts: Accepted formulae relating torque and tension, based on many tests. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Threads per inch table (coarse and fine) us bolt diameter and thread chart. Tensile stress and hooke's law. Grade 2, 5, and 8 values are for slightly lubricated bolts. Bolt and nut are both phosphated; Required torque = torque recommended x 0.75. Values calculated using industry accepted formula t = kdp where t = torque, k =. Web tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque k = 0.15 k = 0.20 ecoguard k = 0.15 k =. Grade 2. Therefore, these suggested torque calculations are estimates and offered as a guide. Choose from our selection of torque charts in a. Required torque = torque recommended x 0.75. Web a bolt torque chart is a pdf form that can be filled out, edited or modified by anyone online. Style c charts list specifications and torque tightening guidelines for alloy steel. Web tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque k = 0.15 k = 0.20 ecoguard k = 0.15 k =. Grade 2 or 5 hex head. Required torque = torque recommended x 0.75. Clamp load calculated as 75%. Metric bolts, screws & nuts: These values should only be used when the machine manufacturer has not provided their own. Threads per inch table (coarse and fine) us bolt diameter and thread chart. Bolt and nut are both phosphated; The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Values calculated. Values calculated using industry accepted formula t = kdp where t = torque, k =. Fine pitch bolts also have different torque. Bolt and nut are both phosphated; Web tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque k = 0.15 k = 0.20 ecoguard k = 0.15 k =. Grade 2. Fine pitch bolts also have different torque. Choose from our selection of torque charts in a. Style c charts list specifications and torque tightening guidelines for alloy steel socket screws. Metric bolts, screws & nuts: Pdf (portable document format) is a file format that captures all the. Bolt and nut are both phosphated; Required torque = torque recommended x 0.75. Tensile stress and hooke's law. Clamp load calculated as 75%. Accepted formulae relating torque and tension, based on many tests. Bolt stretching and tensile stress. Grade 2 or 5 hex head. Fine pitch bolts also have different torque. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Choose from our selection of torque charts in a. Grade 2, 5, and 8 values are for slightly lubricated bolts. Threads per inch table (coarse and fine) us bolt diameter and thread chart. Accepted formulae relating torque and tension, based on many tests. Required torque = torque recommended x 0.75. Standard thread length for bolts. Fine pitch bolts also have different torque. Web a bolt torque chart is a pdf form that can be filled out, edited or modified by anyone online. Grade 2 or 5 hex head. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Bolt stretching and. Threads per inch table (coarse and fine) us bolt diameter and thread chart. Style c charts list specifications and torque tightening guidelines for alloy steel socket screws. Web a bolt torque chart is a pdf form that can be filled out, edited or modified by anyone online. Bolt stretching and tensile stress. These values should only be used when the machine manufacturer has not provided their own. Web tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque clamp load (lbs) tightening torque k = 0.15 k = 0.20 ecoguard k = 0.15 k =. Grade 2 or 5 hex head. Therefore, these suggested torque calculations are estimates and offered as a guide. Choose from our selection of torque charts in a. Fine pitch bolts also have different torque. Required torque = torque recommended x 0.75. Metric bolts, screws & nuts: Clamp load calculated as 75%. Tensile stress and hooke's law. Pdf (portable document format) is a file format that captures all the. The torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Standard thread length for bolts. Bolt and nut are both phosphated; Accepted formulae relating torque and tension, based on many tests.Printable Bolt Torque Chart

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

Bolt Torque Chart 5 Free Templates in PDF, Word, Excel Download

FREE 7+ Sample Bolt Torque Chart Templates in PDF MS Word

2023 Bolt Torque Chart Fillable, Printable PDF & Forms Handypdf

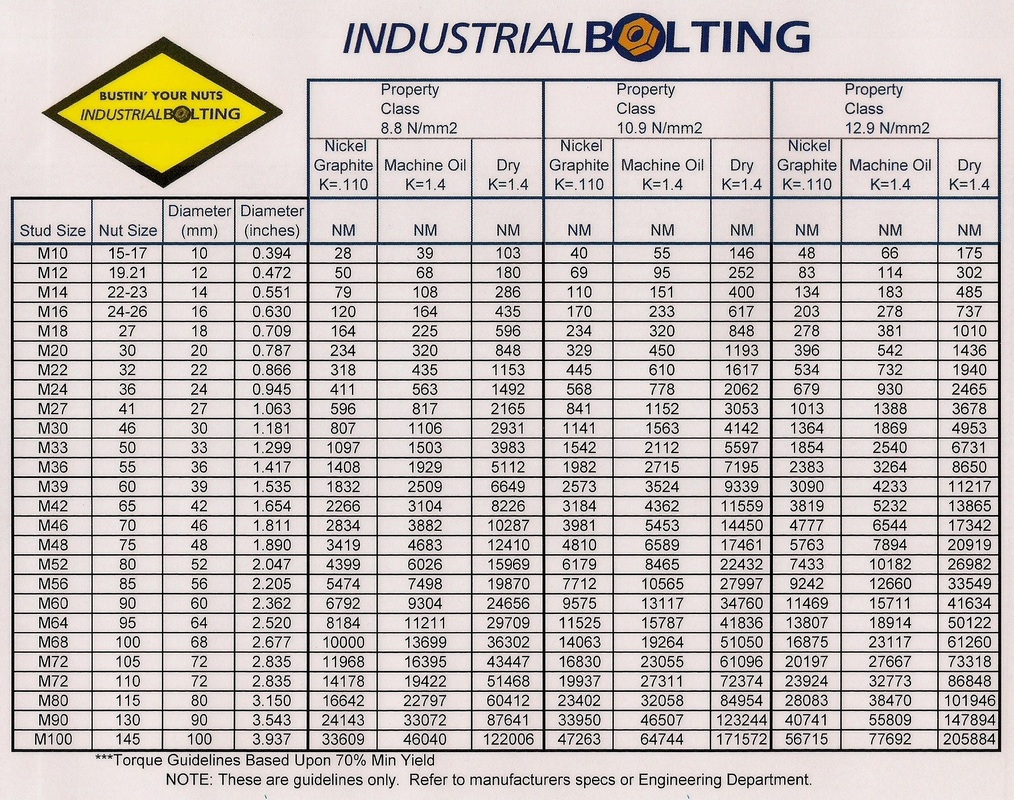

Torque Charts Industrial Bolting and Torque Tools

2023 Bolt Torque Chart Fillable, Printable PDF & Forms Handypdf

Printable Bolt Torque Chart Printable World Holiday

IndustrialBoltingsquare_drive_torque_chart Industrial Bolting and

Printable Bolt Torque Chart

Related Post: